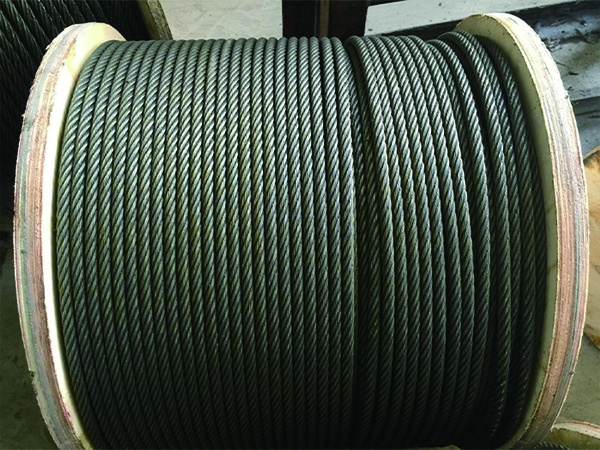

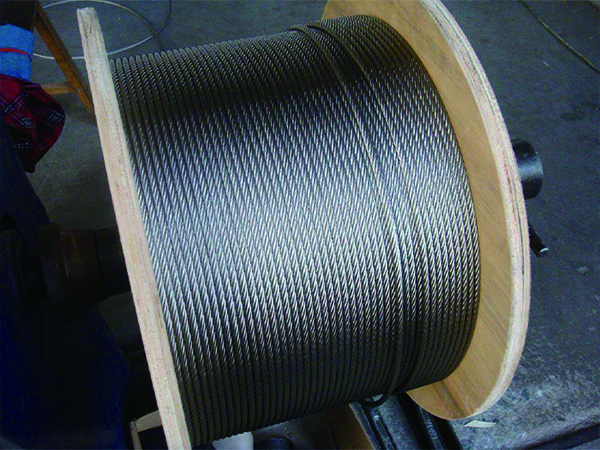

Description

Galvanized steel wire ropes with dimensions of 1, 1.5, 2.0, 2.5, 3.0, 3.6, 4.0, 5.0, 6.0, 7.7, and 9.3 are in millimeters, and the specifications are cold galvanized steel wire ropes and hot galvanized steel wire ropes. Galvanized steel wire is mainly used to stretch carbon structural steel, which is then galvanized to form galvanized iron wire. Galvanized iron wire has good toughness and elasticity, and the maximum amount of zinc can reach 300 grams/square meter. Galvanized wire can be divided into hot-dip galvanized wire and electroplated zinc wire. Cold galvanized wire has a bright silver white color with yellow, while hot-dip galvanized wire has a bright white color.

Working Condition

1.When the steel wire rope comes into contact with the welding wire during lifting operations, it will wear out the insulation layer of the wire, and the generated electric sparks will burn and melt the steel wire of the steel wire rope, resulting in a decrease in its load-bearing capacity until it is scrapped. If it is not detected during construction, the steel wire rope will break and the equipment will fall.

2. When the steel wire rope comes into contact with the power cord and abrades the insulation layer of the wire, it causes the steel wire rope to become live and the entire working surface to be in a live state, resulting in the occurrence of electric shock accidents. When formulating construction plans and setting specific equipment, efforts should be made to avoid both. When unavoidable, isolation and insulation protection measures should be taken.

3. Improper maintenance of steel wire rope and failure to use according to usage regulations. The consequence is that steel wire rope is the most widely used type of rope in lifting and hoisting. However, if it is not used according to the regulations during the hoisting process and not maintained after the hoisting is completed, it will accelerate the scrapping of steel wire rope, increase engineering costs, affect safe construction, and cause safety accidents.

Features

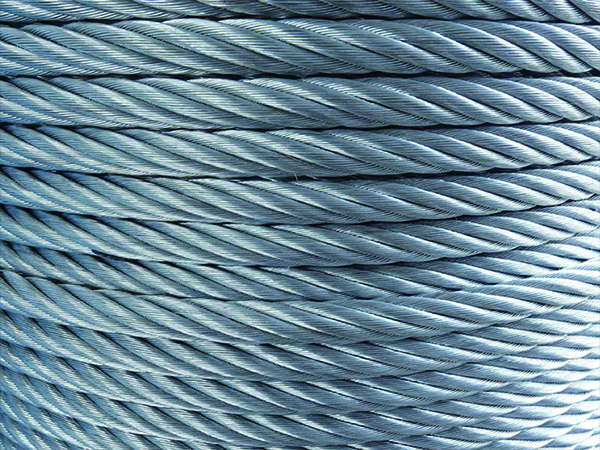

High toughness and less prone to fracture.

Adopting advanced wire drawing machines to reduce twisting and knotting of steel wires during the pulling process, with good cooling performance and improved steel wire performance.

Precision machining layer by layer quality inspection.

7 * 19 ultra soft model, 133 steel wires tightly wrap around the rope head without looseness, ensuring a high-quality product and user experience for users.

Technical Data

| Wire rope MM | Total cross-sectional area of steel wire ( mm) | Weight(kg/100m | Total breaking force of steel wire=nominal tensile strength (1870Mpa) * total cross-sectional area of steel wire (mm ²)Breaking force of steel wire=total breaking force of steel wire * conversion coefficient (0.82) Safety load capacity of steel wire rope=Steel wire breaking force/Safe load factor (4.0) | ||||

| (mm) | Total breaking force of steel wire (t) | Breaking force of steel wire (t) | Safe load capacity of steel wire rope (t) | ||||

| 8.7 | 0.4 | 27.88 | 26.21 | 5.32 | 4.36 | 1.09 | |

| 11.0 | 0.5 | 43.57 | 40.95 | 8.31 | 6.82 | 1.70 | |

| 13.0 | 0.6 | 62.74 | 58.97 | 11.97 | 9.82 | 2.45 | |

| 15.0 | 0.7 | 85.39 | 80.27 | 16.29 | 13.36 | 3.34 | |

| 17.5 | 0.8 | 111.53 | 104.84 | 21.28 | 17.45 | 4.36 | |

| 19.5 | 0.9 | 141.16 | 132.69 | 26.94 | 22.09 | 5.52 | |

| 21.5 | 1.0 | 174.27 | 163.81 | 33.25 | 27.27 | 6.82 | |

| 24.0 | 1.1 | 210.87 | 198.21 | 40.24 | 32.99 | 8.25 | |

| 26.0 | 1.2 | 250.95 | 235.89 | 47.89 | 39.27 | 9.82 | |

| 28.0 | 1.3 | 294.52 | 276.84 | 56.20 | 46.08 | 11.52 | |

| 30.0 | 1.4 | 341.57 | 321.07 | 65.18 | 53.45 | 13.36 | |

Service

1.Providing standardized and specification-compliant products.

2.Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

1.All products come with an 18-month warranty period.

2.Replacement of damaged components (non-human-induced) is provided during the warranty period.

We offer free technical advice for life to all our customers.

90% of the crane spare parts manufactured in our factory, we are able to supply our customers with the parts they need in the first instance and guarantee their suitability for use.

We provide professional installation teams for customers in need to ensure the safe and effective operation of our products.

We provide over 200 types of cranes and their related products, saving customers’ purchasing time.