Description

The collector is one of the most important components in the sliding wire system.

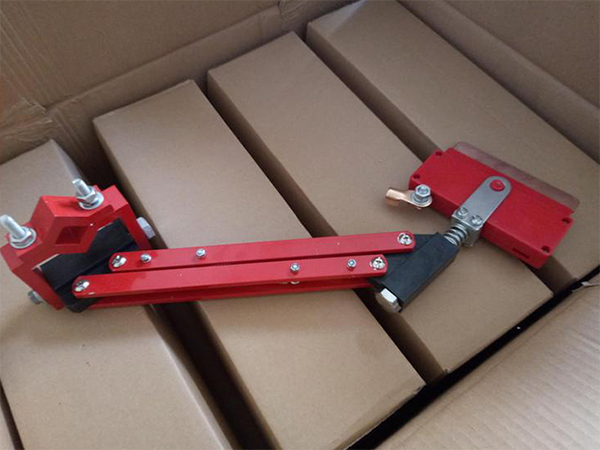

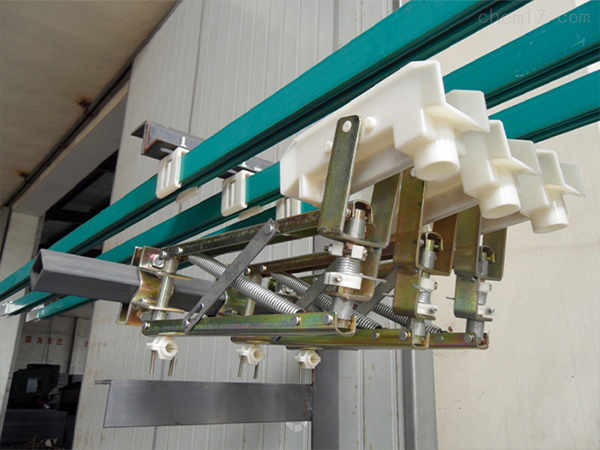

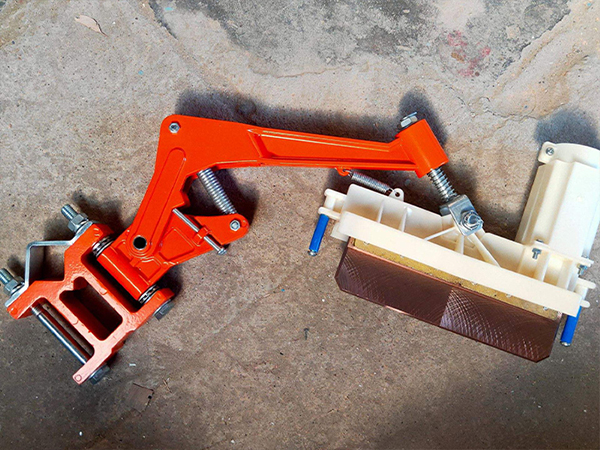

The collector is the main device for picking up electrical energy on the collector side in the sliding contact line system. It directly conducts electrical energy to the consumer through the sliding contact between the collector brush and the guide rail, thereby achieving mobile power supply of the system. The collector consists of two parts: a tension device with a mechanical structure and a collector brush that directly slides in contact with the guide rail.

Working Condition

1. Install fixing bracket: Select a suitable installation fixing bracket according to the actual situation and design requirements, and install it.

2. Install the current collector: Install the current collector on the fixing bracket as required and secure the screws.

3. Connecting the contact network: After the installation of the collector is completed, the connection equipment between the contact network and the vehicle body needs to be connected to the collector.

4. Debugging and Testing: After installation is completed, a series of debugging and testing are required on the vehicle collector to ensure its normal operation.

Features

High safety, using remote control, no need for personnel to come in front of it for manipulation.

Good insulation performance, timely touch the sliding contact wire with your hand, and there is no risk of electric shock.

Energy conservation and environmental protection. The new product collector has the function of energy conservation, with low electricity consumption and no pollution.

Long service life, sliding contact wire, collector, etc. have a very long service life and can be used for a long time.

Technical Data

| Model | Nominal cross-section (mm²) | Current carrying capacity(A) | |||||

| FC=20% | FC=40% | FC=60% | FC=80% | FC=100% | |||

| JGHL—240 | 240 | 1000 | 700 | 600 | 510 | 430 | |

| JGHL—320 | 320 | 1250 | 950 | 780 | 650 | 550 | |

| JGHL—480 | 480 | 1900 | 1400 | 1150 | 960 | 850 | |

| JGHL—640 | 640 | 2500 | 1900 | 1550 | 1300 | 1150 | |

| JGHL—800 | 800 | 3150 | 2350 | 1950 | 1600 | 1400 | |

| JGHL—1000 | 1000 | 3950 | 2900 | 2400 | 2000 | 1800 | |

| JGHL—1500 | 1500 | 5900 | 4400 | 3750 | 3050 | 2700 | |

| JGHL—1800 | 1800 | 7050 | 5300 | 4450 | 3700 | 3200 | |

Service

1.Providing standardized and specification-compliant products.

2.Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

1.All products come with an 18-month warranty period.

2.Replacement of damaged components (non-human-induced) is provided during the warranty period.

We offer free technical advice for life to all our customers.

90% of the crane spare parts manufactured in our factory, we are able to supply our customers with the parts they need in the first instance and guarantee their suitability for use.

We provide professional installation teams for customers in need to ensure the safe and effective operation of our products.

We provide over 200 types of cranes and their related products, saving customers’ purchasing time.