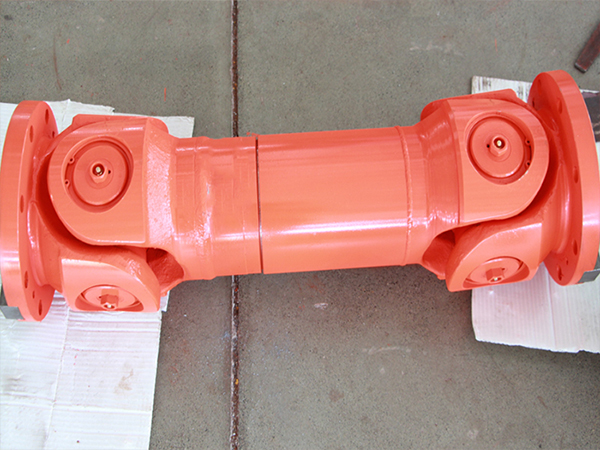

Description

SWC type universal joint is a type of universal joint, mainly divided into two categories: non expansion joint type (model DDH62) and expansion joint type (model DDH61). A mechanical component used to connect two shafts (driving shaft and driven shaft) in different mechanisms when there is eccentricity or deviation in the product, so that the two shafts rotate together to achieve the effect of transmitting torque. In some high-speed and heavy-duty power transmission scenarios, some universal joint products can also play a certain role in buffering, vibration reduction, and improving the dynamic performance of the shaft system.

Working Condition

1. The balance plate or component on the universal joint has not undergone dynamic balance compensation.

2. During assembly, the two universal joints of the same ten thousand directional coupling are not in the same plane.

3. The bending of the universal joint, the depression of the shaft tube, the failure to align the marks during the assembly of the transmission shaft, or the tilting of the universal joint fork and spline shaft when welding with the shaft tube, have damaged the dynamic balance of the original components.

4. Loose bolts connecting the flange plate of the universal joint cause the position of the universal joint to deviate.

5. The spline shaft of the universal joint and the sleeve fork have excessive wear and clearance.

Features

It has a large angle compensation ability, with a SWC type axis angle of up to 15 and a SWP type angle of around 10.

The structure is compact and reasonable. The SWC model adopts an integral fork head, making transportation more reliable.

It has a large carrying capacity. Compared with other types of couplings with the same rotation diameter, the torque transmitted by them is greater, which makes the matching range of mechanical equipment with limited rotation diameter more advantageous.

High transmission efficiency. Its transmission efficiency reaches 98-99.8%, which is used for high-power transmission and has a significant energy-saving effect.

Smooth transportation, low noise, and convenient installation, disassembly, and maintenance.

Technical Data

| Model | Rotating diameter D mm | Revolution torque Tn (KN:m) | Fatigue torque Tf (KN.m) | Size (mm) | Moment of inertia 1 (kg÷m) | Weight G (kg) | ||||||||||||

| Axis Fold angle ≥P Lmin | Dt (js11) | D (H7) | D3 | Lm | n-d | k | t | B (h9) | B | Lmin | 100mm | Lmin | 100mm | |||||

| SWC180WF | 180 | 12.5 | 6.3 | 25° | 560 | 155 | 105 | 114 | 110 | 8-17 | 17 | 5.5 | 0.2480 | 0.0070 | 58 | 2.8 | ||

| SWC225WF | 225 | 40 | 20 | 15 | 610 | 196 | 135 | 152 | 120 | 8-17 | 20 | 5 | 32 | 9.0 | 0.636 | 0.0234 | 93 | 4.9 |

| SWC250WF | 250 | 63 | 31.5 | 15 | 715 | 218 | 150 | 168 | 140 | 8-19 | 25 | 6 | 40 | 12.5 | 1.325 | 0.0277 | 143 | 5.3 |

| SWC285WF | 285 | 90 | 45 | 15° | 810 | 245 | 170 | 194 | 160 | 8-21 | 27 | 7 | 40 | 15.0 | 2.664 | 0.0510 | 222 | 6.3 |

| SWO315WF | 315 | 125 | 63 | 15° | 915 | 284 | 185 | 219 | 180 | 10-23 | 32 | 8 | 40 | 15.0 | 4.469 | 0.0795 | 300 | 8.0 |

| SWC350WF | 350 | 180 | 90 | 15° | 980 | 310 | 210 | 267 | 194 | 10-23 | 35 | 8 | 50 | 16.0 | 7.388 | 0.2219 | 412 | 15.0 |

| SWC390WF | 390 | 250 | 125 | 15° | 1100 | 345 | 235 | 267 | 215 | 10-25 | 40 | 8 | 70 | 18.0 | 13.184 | 0.2219 | 588 | 15.0 |

| SWC440WF | 440 | 355 | 180 | 15 | 1290 | 390 | 255 | 325 | 260 | 16-28 | 42 | 10 | 80 | 20.0 | 23.250 | 0.4744 | 880 | 21.7 |

| SWC490WF | 490 | 500 | 250 | 15² | 1360 | 435 | 275 | 325 | 270 | 16-31 | 47 | 12 | 90 | 22.0 | 40.750 | 0.4744 | 1173 | 21.7 |

| SWC550WF | 550 | 710 | 355 | 15 | 1510 | 492 | 320 | 426 | 305 | 16-31 | 50 | 12.0 | 100 | 22.5 | 68,480 | 1.3570 | 1663 | 34.0 |

| SWC620WF | 620 | 1000 | 500 | 15° | 1690 | 555 | 380 | 426 | 340 | 16-38 | 55 | 12 | 100 | 25.0 | 27.53 | 1.3570 | ||

Service

1.Providing standardized and specification-compliant products.

2.Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

1.All products come with an 18-month warranty period.

2.Replacement of damaged components (non-human-induced) is provided during the warranty period.

We offer free technical advice for life to all our customers.

90% of the crane spare parts manufactured in our factory, we are able to supply our customers with the parts they need in the first instance and guarantee their suitability for use.

We provide professional installation teams for customers in need to ensure the safe and effective operation of our products.

We provide over 200 types of cranes and their related products, saving customers’ purchasing time.