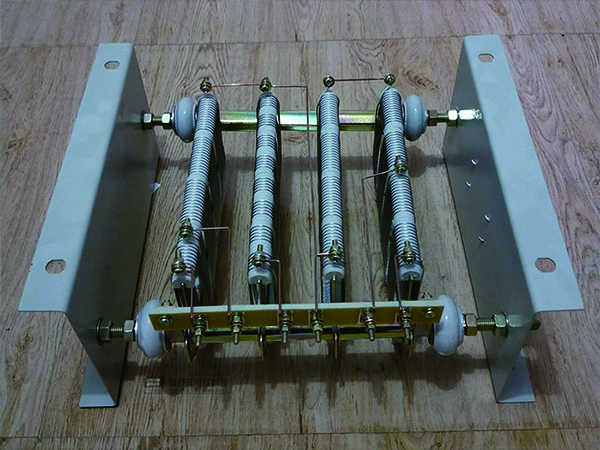

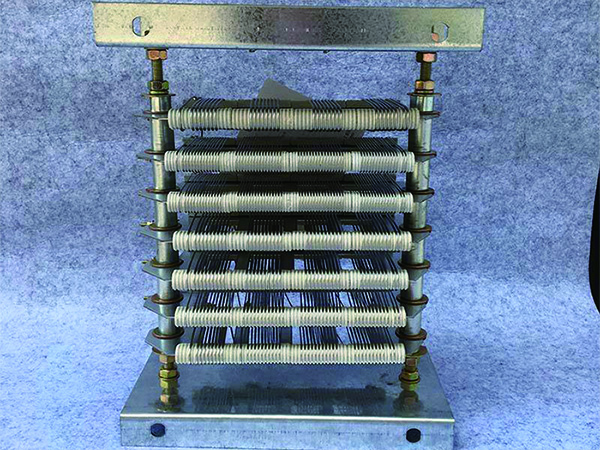

Description

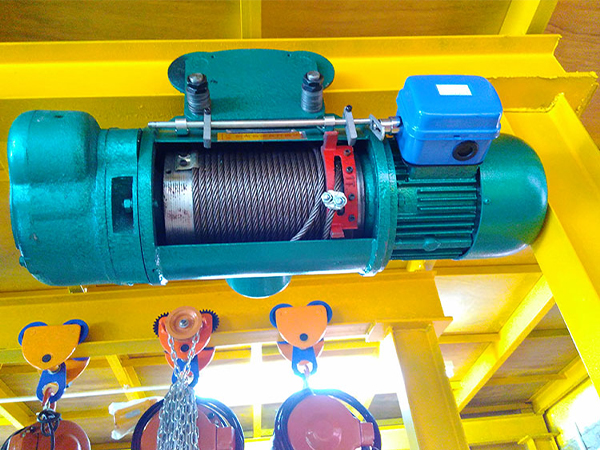

The crane resistor is suitable for coordinating in circuits with AC 50Hz and low voltage up to 660V, to control the starting and braking of the motor.

Working Condition

1. Environmental temperature: The working environment of the crane resistor should be between -5 ℃ and+40 ℃. If the environmental temperature is not within this range, it will affect the mechanical strength of the materials and components inside the resistor, leading to failure and other faults.

2. Dust, moisture, corrosion and other environmental factors: In industrial production sites, crane resistors often come into contact with dust, moisture, and corrosive gases. These environmental factors can affect resistors, causing short circuits or insulation failure, leading to crane failure. Therefore, these environments should be avoided as much as possible.

3. Power supply voltage: The rated voltage of the crane resistor must be consistent with the power supply voltage. If the power supply voltage is too high, it will accelerate the internal heat loss of the resistor, shorten the lifespan of the resistor, or directly damage electrical components.

4. Load current: Load current is one of the important parameters for the operation of crane resistors, and its size should be suitable for the rated current of the resistor. If the load current is too large, it will make the resistor easily damaged or burned out.

5. Installation location: The crane resistor should be installed in a cool and ventilated place, and should not be installed near heat sources or in areas exposed to direct sunlight to avoid accelerating the aging and failure of the resistor.

Features

Rated voltage: usually 380V, but there are also other specifications such as 440V, 660V, etc.

Rated current: usually 10A-500A. The current of different types of resistors varies and needs to be selected according to the specific load situation of the crane.

Voltage withstand level: usually 2.5kV, but there are other specifications such as 5kV, 10kV, etc.

Resistance range: usually 0.1 Ω -50 Ω. The resistance range of different types of resistors varies and needs to be selected according to specific crane control requirements.

External dimensions: There are many types of external dimensions for resistors, and the appropriate size can be selected based on the size and installation position of different crane bodies.

Technical Data

| Model | Resistance value(Ω) | Resistance Tolerance(%) | Rated Current (A) | Insulation power (KW) | Insulation voltage (KV) | Fever time constant (S) | Operating temperature range | Composition resistor | |

| Model | Number | ||||||||

| ZX2-1/0.2 | 0.2 | ±10% | 43 | 3.5KW | 2.5KV | 180 | -55℃~+315℃ | ZX2-1/0.2 | 10 |

| ZX2-1/0.25 | 0.25 | ±10% | 38 | 3.5KW | 2.5KV | 160 | -55℃~+315℃ | ZX2-1/0.25 | 10 |

| ZX2-1/0.35 | 0.35 | ±10% | 32 | 3.5KW | 2.5KV | 140 | -55℃~+315℃ | ZX2-1/0.35 | 10 |

| ZX2-1/0.4 | 0.4 | ±10% | 29 | 3.5KW | 2.5KV | 126 | -55℃~+315℃ | ZX2-1/0.4 | 10 |

| ZX2-1/0.5 | 0.5 | ±10% | 26 | 3.5KW | 2.5KV | 113 | -55℃~+315℃ | ZX2-1/0.5 | 10 |

| ZX2-1/0.66 | 0.66 | ±10% | 23 | 3.5KW | 2.5KV | 100 | -55℃~+315℃ | ZX2-1/0.66 | 10 |

| ZX2-2/0.7 | 0.7 | ±10% | 22.3 | 3.5KW | 2.5KV | 286 | -55℃~+315℃ | ZX2-2/0.7 | 10 |

| ZX2-2/0.9 | 0.9 | ±10% | 19.9 | 3.5KW | 2.5KV | 237 | -55℃~+315℃ | ZX2-2/0.9 | 10 |

| ZX2-2/1.1 | 1.1 | ±10% | 17.7 | 3.5KW | 2.5KV | 203 | -55℃~+315℃ | ZX2-2/1.1 | 10 |

| ZX2-2/1.26 | 1.26 | ±10% | 16.7 | 3.5KW | 2.5KV | 186 | -55℃~+315℃ | ZX2-2/1.26 | 10 |

| ZX2-2/1.45 | 1.45 | ±10% | 15.4 | 3.5KW | 2.5KV | 169 | -55℃~+315℃ | ZX2-2/1.45 | 10 |

| ZX2-2/1.95 | 1.95 | ±10% | 13.8 | 3.5KW | 2.5KV | 132 | -55℃~+315℃ | ZX2-2/1.95 | 10 |

| ZX2-2/2.8 | 2.8 | ±10% | 11.2 | 3.5KW | 2.5KV | 282 | -55℃~+315℃ | ZX2-2/2.8 | 10 |

| ZX2-2/3.5 | 3.5 | ±10% | 10.1 | 3.5KW | 2.5KV | 235 | -55℃~+315℃ | ZX2-2/3.5 | 10 |

| ZX2-2/4.4 | 4.4 | ±10% | 8.9 | 3.5KW | 2.5KV | 202 | -55℃~+315℃ | ZX2-2/4.4 | 10 |

| ZX2-2/5.0 | 5 | ±10% | 8.4 | 3.5KW | 2.5KV | 214 | -55℃~+315℃ | ZX2-2/5.0 | 10 |

| ZX2-2/5.8 | 5.8 | ±10% | 7.7 | 3.5KW | 2.5KV | 168 | -55℃~+315℃ | ZX2-2/5.8 | 10 |

| ZX2-2/8 | 8 | ±10% | 6.6 | 3.5KW | 2.5KV | 132 | -55℃~+315℃ | ZX2-2/8 | 10 |

| ZX2-2/12 | 12 | ±10% | 5.4 | 3.5KW | 2.5KV | 175 | -55℃~+315℃ | ZX2-2/12 | 10 |

| ZX2-2/14 | 14 | ±10% | 5 | 3.5KW | 2.5KV | 153 | -55℃~+315℃ | ZX2-2/14 | 10 |

| ZX2-2/18 | 18 | ±10% | 4.4 | 3.5KW | 2.5KV | 132 | -55℃~+315℃ | ZX2-2/18 | 10 |

| ZX2-2/21.6 | 21.6 | ±10% | 4 | 3.5KW | 2.5KV | 112 | -55℃~+315℃ | ZX2-2/21.6 | 10 |

| ZX2-2/27.6 | 27.6 | ±10% | 3.5 | 3.5KW | 2.5KV | 104 | -55℃~+315℃ | ZX2-2/27.6 | 10 |

| ZX2-2/37 | 37 | ±10% | 3.1 | 3.5KW | 2.5KV | 122 | -55℃~+315℃ | ZX2-2/37 | 10 |

| ZX2-2/48 | 48 | ±10% | 2.7 | 3.5KW | 2.5KV | 104 | -55℃~+315℃ | ZX2-2/48 | 10 |

| ZX2-2/68 | 68 | ±10% | 2.3 | 3.5KW | 2.5KV | 86 | -55℃~+315℃ | ZX2-2/68 | 10 |

| ZX2-2/96 | 96 | ±10% | 1.9 | 3.5KW | 2.5KV | 75 | -55℃~+315℃ | ZX2-2/96 | 10 |

| ZX2-2/140 | 140 | ±10% | 1.6 | 3.5KW | 2.5KV | 63 | -55℃~+315℃ | ZX2-2/140 | 10 |

| ZX2-2/188 | 188 | ±10% | 1.4 | 3.5KW | 2.5KV | 52 | -55℃~+315℃ | ZX2-2/188 | 10 |

| ZX2-2/260 | 260 | ±10% | 1.2 | 3.5KW | 2.5KV | 41 | -55℃~+315℃ | ZX2-2/260 | 10 |

Service

1.Providing standardized and specification-compliant products.

2.Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

1.All products come with an 18-month warranty period.

2.Replacement of damaged components (non-human-induced) is provided during the warranty period.

We offer free technical advice for life to all our customers.

90% of the crane spare parts manufactured in our factory, we are able to supply our customers with the parts they need in the first instance and guarantee their suitability for use.

We provide professional installation teams for customers in need to ensure the safe and effective operation of our products.

We provide over 200 types of cranes and their related products, saving customers’ purchasing time.