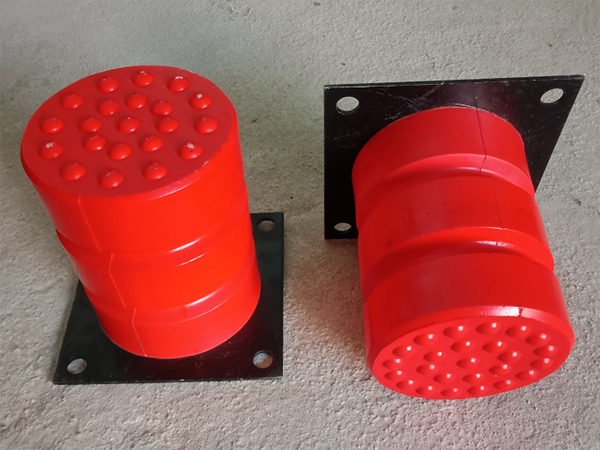

Description

The polyurethane buffer is lightweight, easy to install, does not require maintenance, has good buffering effect, is resistant to impact, and has good compressive performance. During the buffering process, there is no noise, no sparks, good explosion-proof performance, and stability.

Polyurethane buffer is suitable for metallurgy, mining, railways, ports, ships, automobiles, scales, large machinery, equipment, and other fields. Polyurethane buffer has become a buffer for the crane and elevator industry, and can also be used for various front and rear corners of car vans to prevent collisions.

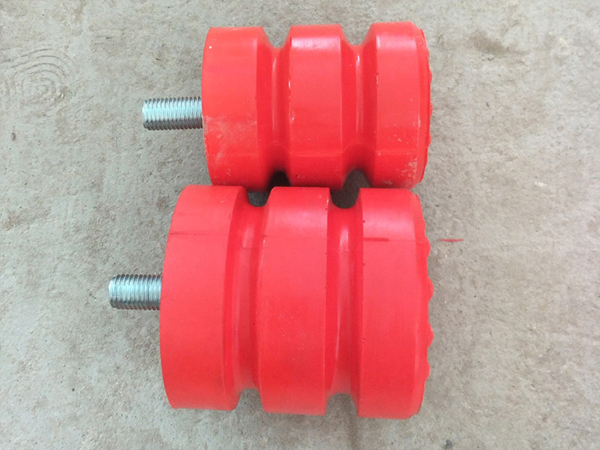

Classification of polyurethane buffer

Working Condition

The ambient temperature shall not exceed+40 ℃, and the average temperature within 24 hours shall not exceed+35 ℃;

The ambient temperature shall not be lower than -15 ℃; The relative humidity shall not exceed 50% at a temperature of+40 ℃.

Features

Regular testing (at least once per episode):

It should be avoided to use under low temperature (below -40 ° C) or high temperature (above 80%) and humidity (above 85%) and other environmental conditions:

It should not be used under strong acidic or alkaline environmental conditions.

Technical Data

| Item | Model | D mm | H mm | h mm | B mm | b mm | mm | Buffer capacity kn.m | cushion stroke mn | Cushioning force kn |

| 1 | JHQ-C-1 | 65 | 80 | 8 | 100 | 70 | 12 | 0.265 | 60 | 28 |

| 2 | JHO-C-2 | 80 | 80 | 8 | 115 | 85 | 12 | 0.400 | 60 | 42 |

| 3 | JHO-C-3 | 80 | 100 | 8 | 115 | 85 | 12 | 0.502 | 75 | 42 |

| 4 | JHO-C-4 | 100 | 80 | 8 | 130 | 100 | 14 | 0.628 | 60 | 66 |

| 5 | JHO-C-5 | 100 | 100 | 8 | 130 | 100 | 14 | 0.785 | 75 | 66 |

| 6 | JHO-C-6 | 100 | 125 | 8 | 130 | 100 | 14 | 0.980 | 94 | 66 |

| 7 | JHO-C- | 125 | 100 | 10 | 165 | 130 | 14 | 1.227 | 75 | 103 |

| 8 | JHO-C-8 | 125 | 125 | 10 | 165 | 130 | 14 | 1.533 | 94 | 103 |

| 9 | JHO-C-9 | 125 | 160 | 10 | 165 | 130 | 14 | 1.960 | 120 | 103 |

| 10 | ,IHO-C-10 | 160 | 125 | 10 | 200 | 160 | 18 | 2.512 | 94 | 169 |

| 11 | JHO-C-11 | 160 | 160 | 10 | 200 | 160 | 18 | 3.125 | 120 | 169 |

| 12 | JHO-C-12 | 160 | 200 | 10 | 200 | 160 | 18 | 4.019 | 150 | 169 |

| 13 | JHO-C-13 | 200 | 160 | 12 | 250 | 200 | 18 | 5.024 | 120 | 265 |

| 14 | JHO-C-14 | 200 | 200 | 12 | 250 | 200 | 18 | 6.280 | 150 | 265 |

| 15 | JHO-C-15 | 200 | 250 | 12 | 250 | 200 | 18 | 7.850 | 188 | 265 |

| 16 | JHO-C-16 | 250 | 200 | 12 | 320 | 250 | 22 | 9.810 | 150 | 414 |

| 17 | JHO-C-17 | 250 | 250 | 12 | 320 | 250 | 22 | 12.266 | 188 | 414 |

| 18 | JHO-C-18 | 250 | 320 | 12 | 320 | 250 | 22 | 15.700 | 240 | 414 |

| 19 | JHO-C-19 | 320 | 250 | 14 | 400 | 315 | 22 | 20.096 | 188 | 675 |

| 20 | JHO-C-20 | 320 | 320 | 14 | 400 | 315 | 22 | 25.732 | 240 | 675 |

| 21 | JHO-C-21 | 320 | 400 | 14 | 400 | 315 | 22 | 32.154 | 300 | 675 |

| 22 | JHO-C-22 | 320 | 450 | 14 | 400 | 315 | 22 | 36.17 | 337 | 675 |

| 23 | JHO-C-23 | 400 | 450 | 14 | 460 | 370 | 22 | 56.5 | 337 | 1054 |

| 24 | JHO-C-24 | 400 | 300 | 14 | 460 | 370 | 22 | 37.7 | 225 | 1054 |

Service

1.Providing standardized and specification-compliant products.

2.Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

1.All products come with an 18-month warranty period.

2.Replacement of damaged components (non-human-induced) is provided during the warranty period.

We offer free technical advice for life to all our customers.

90% of the crane spare parts manufactured in our factory, we are able to supply our customers with the parts they need in the first instance and guarantee their suitability for use.

We provide professional installation teams for customers in need to ensure the safe and effective operation of our products.

We provide over 200 types of cranes and their related products, saving customers’ purchasing time.