Description

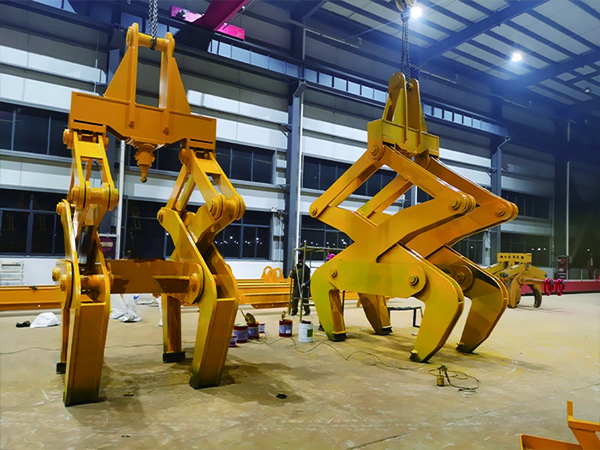

Electric rotary clamps are mainly used for off-line lifting, stacking, loading and unloading of billets and slabs, etc. The front part uses a gravity clamp, the rotating part is electric, and the rotating mechanism uses a brake motor cycloid needle the wheel reducer can achieve 360-degree two-way free rotation, and can automatically brake after rotation, improving safety and reliability during the transportation process. At the same time, a first-level gear reduction device is added to reduce the rotation speed and improve the control ability of the rotation angle.

Working Condition

1. Before operation, you should be familiar with the working principle, results and precautions of the equipment, and receive relevant training.

2. Before operation, check whether all parts of the vehicle equipment are normal and whether the connections are firm.

3. Operators must be familiar with the safe operating procedures of the equipment and remain alert at all times during operation.

4.Use the correct clamp to ensure that the parts are not damaged or deformed during the clamping process.

5.Determine the clamping force to be added to ensure sufficient clamping force to avoid movement or sliding of parts.

6.Operators must wear protective equipment and comply with relevant regulations

Features

Clamp with mechanical automatic switching

The motor is equipped with fequency converter

Using the lever principle, the object can be clamped without the assistance of external force. The clamping is reliable, the action is flexible, and the lifting is safe and reliable

Technical Data

| Specification (mm) | Steel coil parameters (MM) | Fixture opening A | Size(MM) | ||

| B | C | D | |||

| 8T | ID:500 | 250-1900 | 1000 | 2700 | 2900 |

| OD:2200 | 1000 | 2700 | 2900 | ||

| 15T | ID:500 | 250-1900 | 1000 | 2700 | 2900 |

| OD:2200 | 1000 | 2700 | 2900 | ||

| 30T | ID:500 | 250-1900 | 1000 | 2700 | 2900 |

| OD:2200 | 1000 | 2700 | 2900 | ||

Service

1.Providing standardized and specification-compliant products.

2.Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

1.All products come with an 18-month warranty period.

2.Replacement of damaged components (non-human-induced) is provided during the warranty period.

We offer free technical advice for life to all our customers.

90% of the crane spare parts manufactured in our factory, we are able to supply our customers with the parts they need in the first instance and guarantee their suitability for use.

We provide professional installation teams for customers in need to ensure the safe and effective operation of our products.

We provide over 200 types of cranes and their related products, saving customers’ purchasing time.