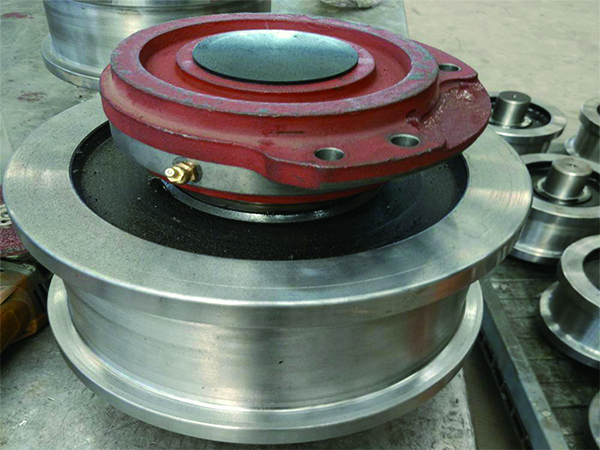

Description

Couplings are commonly used components in mechanical devices, mainly used to connect shafts to transmit motion and torque, and can also be used as safety devices. Couplings are used to connect two shafts together. The two shafts cannot be separated during machine operation, and can only be separated when the machine is stopped; There are various types of couplings, and when selecting standard parts or designing them, factors such as torque transmission, rotational speed, torsional stiffness variation, volume size, buffering and vibration absorption capacity should be considered.

Working Condition

1. The coupling is not allowed to have more than the specified shaft line skew and radial displacement, so as not to affect its transmission performance.

2. The bolts of the coupling shall not be loose or defective.

3. The gear coupling and cross coupling should be lubricated regularly, generally once every 2~3 months, so as to avoid severe wear of the gear teeth and cause serious consequences.

Features

The structure is simple, easy to maintain, maintenance-free, and can be operated continuously for a long time.

It has a large load-bearing capacity and has good vibration damping, cushioning and electrical insulation properties.

It has a large axial, radial and angular compensation capacity.

The radial size is small, the weight is light, the moment of inertia is small, and it is suitable for medium and high speed occasions.

Technical Data

| Type | Nominal torque(KN·m) | Allowable speed(r/min) | Shaft hole diameter(d1,d2) | Shaft hole length(Y,J1,Z1) | D | D1 | D2 | D3 | C | kg |

| CLZ1 | 0.71 | 3780 | 18-40(60) | 40-142 | 170 | 110 | 55 | 95 | 2.2 | 12.8 |

| CLZ2 | 1.4 | 3000 | 30-50(70) | 82-142 | 185 | 125 | 70 | 110 | 2.5 | 17.5 |

| CLZ3 | 3.15 | 2400 | 40-60(90) | 112-172 | 220 | 150 | 90 | 145 | 2.5 | 33 |

| CLZ4 | 5.6 | 2000 | 45-75(100) | 112-212 | 150 | 175 | 110 | 170 | 2.5 | 47.3 |

| CLZ5 | 8 | 1680 | 50-90(120) | 112-212 | 290 | 200 | 130 | 190 | 5 | 69.8 |

| CLZ6 | 11.2 | 1500 | 60-110(130) | 142-252 | 320 | 230 | 140 | 210 | 5 | 96.1 |

| CLZ7 | 18 | 1270 | 65-120(150) | 142-252 | 350 | 260 | 170 | 240 | 5 | 129 |

| CLZ8 | 23.6 | 1140 | 80-140(170) | 172-352 | 380 | 315 | 190 | 270 | 5 | 179 |

| CLZ9 | 28 | 1000 | 90-160(190) | 212-352 | 430 | 365 | 210 | 280 | 5 | 221 |

| CLZ10 | 50 | 850 | 110-180(220) | 212-410 | 490 | 420 | 260 | 320 | 5 | 328 |

| CLZ11 | 71 | 750 | 120-220(250) | 252-470 | 545 | 470 | 300 | 380 | 5 | 468 |

| CLZ12 | 100 | 660 | 140-250(280) | 302-550 | 590 | 520 | 340 | 420 | 5 | 658 |

Service

1.Providing standardized and specification-compliant products.

2.Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

1.All products come with an 18-month warranty period.

2.Replacement of damaged components (non-human-induced) is provided during the warranty period.

We offer free technical advice for life to all our customers.

90% of the crane spare parts manufactured in our factory, we are able to supply our customers with the parts they need in the first instance and guarantee their suitability for use.

We provide professional installation teams for customers in need to ensure the safe and effective operation of our products.

We provide over 200 types of cranes and their related products, saving customers’ purchasing time.