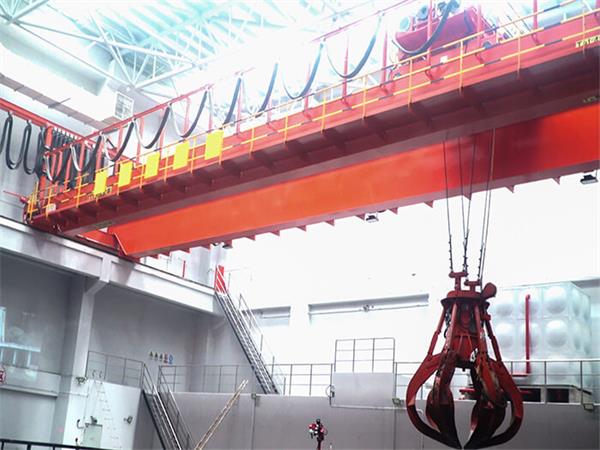

Applications

QZ Type Grab Bridge crane is widely used in loading goods in port, factory, workshop and power plant. It is only suitable for bulk materials in natural stacking conditions. If grabbing the materials under the water or special materials, they must be specialized when ordering.

Working Condition

1.Metal structures and mechanical parts should have sufficient strength, stiffness and buckling resistance.

2. It is required that parts and metal structures are not damaged after being loaded. For parts such as steel wire ropes with complex stress states, static strength calculations are usually carried out based on the main load and main deformation form, and a higher safety factor is used. It must also be required that the deformation of the component under the action of the load is within the allowable range, that is, There should be sufficient stiffness.

Second, the whole machine must have the necessary stability against overturning.

3. The prime mover has the power to meet the operating performance requirements, and the braking device should provide the necessary braking torque.

Features

High security. The safety protection devices are complete, including limit switches, overload protection devices, emergency stop devices, etc. for lifting and CT, to ensure the safety of the operation; During operation, variable frequency control can be carried out to ensure the safe movement and landing of goods;

Flexible operation and stable performance. The gears in the reducer adopt helical gears, which can be automatically lubricated and have better equipment flexibility; Can be remotely controlled for easier operation;

Strong stiffness and good quality. The steel plate raw materials are made of products from top tier factories, with stable and guaranteed quality, low failure rate, and better adaptability to special working conditions;

High work efficiency and good durability. Adopting laser assisted height measurement technology for more accurate positioning; High level of work, supporting all day work and demanding work demands.

Technical Data

| 5T | 10T | |||||||||||||||||

| Span | m | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | |

| Working level | A6 | |||||||||||||||||

| Max lifting height | m | 32 | 30 | |||||||||||||||

| Speed | Lifting | m/min | 28.2 | 39.0 | ||||||||||||||

| Trolley running | 43.5 | 45.4 | ||||||||||||||||

| Big trolley running | 93 | 94 | 86.5 | |||||||||||||||

| Motor | Lifting | kW | YZR255M-8/22 | YZR280M-10/45 | ||||||||||||||

| Trolley running | YZR132M1-6/2.2 | YZR132M2-6/3.7 | ||||||||||||||||

| Big trolley running | YZR160M1-6/2×5.5 | YZR160M2-6/2×7.5 | YZR160M2-6/2×7.5 | |||||||||||||||

| Main size | B | 5700 | 6200 | 5860 | 6260 | |||||||||||||

| W | 4100 | 4600 | 4200 | 4600 | ||||||||||||||

| b | 244 | 274 | ||||||||||||||||

| LX | 2000 | |||||||||||||||||

| H | 1753 | 1756 | 1759 | 1764 | 1767 | 1770 | 1773 | 1776 | 2058 | 2061 | 2064 | 2067 | 2070 | 2073 | 2076 | 2079 | ||

| H2 | 730 | 845 | ||||||||||||||||

| S1 | 1617 | 1860 | ||||||||||||||||

| S2 | 1764 | 1730 | ||||||||||||||||

| F | 26 | 176 | 246 | 326 | 476 | 676 | 776 | 926 | 28 | 148 | 278 | 428 | 578 | 728 | 828 | 978 | ||

| Weight | Trolley | t | 4.5 | 8.33 | ||||||||||||||

| Total weight | 18.1 | 19.8 | 21.9 | 24.1 | 27 | 30.1 | 32.9 | 36 | 27.5 | 29.4 | 31.8 | 34.5 | 37.1 | 40.6 | 43.8 | 46.4 | ||

| Maximum wheel pressure | KN | 86 | 91 | 97 | 103 | 112 | 126 | 129 | 138 | 108 | 117 | 126 | 134 | 142 | 152 | 163 | 168 | |

| Grab | Model | u | U3 | U2 | U1 | U6 | U5 | U4 | ||||||||||

| Type | Light | Middle | Heavy | Light | Middle | Heavy | ||||||||||||

| volume | m^3 | 2.5 | 1.5 | 1 | 5 | 3 | 2 | |||||||||||

Spare Parts

Service

1.Providing standardized and specification-compliant products.

2.Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

1.All products come with an 18-month warranty period.

2.Replacement of damaged components (non-human-induced) is provided during the warranty period.

We offer free technical advice for life to all our customers.

90% of the crane spare parts manufactured in our factory, we are able to supply our customers with the parts they need in the first instance and guarantee their suitability for use.

We provide professional installation teams for customers in need to ensure the safe and effective operation of our products.

We provide over 200 types of cranes and their related products, saving customers’ purchasing time.