Description

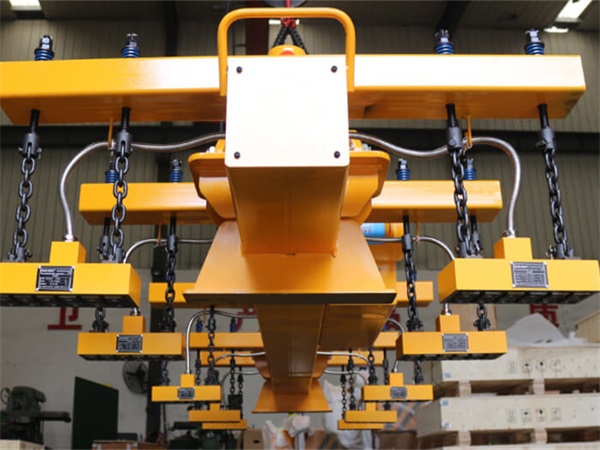

The Electric Permanent Lifter suction cup utilizes the interaction between the electromagnet and the permanent magnet to adsorb the workpiece. When current passes through an electromagnet, a magnetic field is generated, which attracts the permanent magnet. When the current passes through the permanent magnet, an opposite magnetic field is generated to counteract the magnetic field generated by the electromagnet, causing the workpiece to be firmly attached to the suction cup. When the direction of the current changes, the position of the workpiece will also change accordingly.

Working Condition

1. Check before turning on the power: Ensure that the power switch of the electric permanent magnet suction cup is turned off to prevent surges or other unsafe factors.

2. Recognition of magnetic area: Familiarize yourself with the working range of electric permanent magnet suction cups, avoid touching the magnetic substances around the suction cups, and prevent the influence of magnetic force from causing objects to be adsorbed.

3. Keep the suction cup clean: Regularly clean the surface of the suction cup to ensure that there is no oil, impurities, or other substances that may affect its performance.

4. Avoid applying pressure under the suction cup: Any form of pressure can affect magnetic force, leading to adsorption failure or damage to objects.

5. Follow operating procedures: Follow the instructions provided by the manufacturer of the electric permanent magnet suction cup and do not attempt untrained operations.

6. Pay attention to the position of the power cord: Ensure that the power cord does not come into contact with any conductive substances or be trapped to prevent short circuits.

7. Avoid use in damp environments: Electric permanent magnet suction cups should be avoided in damp or excessively humid environments to prevent electric shock or short circuits.

Features

The Electric Permanent Lifter lifting tools and fixtures can be used for lifting and handling various metal and non-metallic materials, such as steel, mechanical parts, automotive manufacturing and other production processes.

Positioning and fixation: Electric permanent magnet fixtures and adsorption devices can be used for positioning and fixation of various metal and non-metal materials, such as metal parts in machine tools and molds, goods in logistics and packaging industries, etc.

Technical Data

| Model | Lifting capacity(kg) | Min Thickness(mm) | Voltage(V) | Chargetime(h) | Size(mm) | Weight (kg) | |||||

| A | B | C | D | d | H | ||||||

| HBEP-500 | 500 | 6 | DC24 | 5-7 | 220 | 390 | 70 | 20 | 50 | 530 | 65 |

| HBEP-1000 | 1000 | 6 | DC24 | 5-7 | 220 | 390 | 85 | 25 | 50 | 545 | 75 |

| HBEP-1500 | 1500 | 10 | DC24 | 6-8 | 220 | 490 | 75 | 30 | 60 | 420 | 180 |

| HBEP-2000 | 2000 | 12 | DC24 | 6-8 | 220 | 490 | 90 | 30 | 60 | 435 | 215 |

| HBEP-3000 | 3000 | 16 | DC48 | 7-9 | 370 | 450 | 100 | 40 | 85 | 550 | 260 |

| HBEP-5000 | 5000 | 20 | DC60 | 7-9 | 540 | 720 | 115 | 40 | 85 | 565 | 380 |

| HBEP-300B | 300 | 4 | DC24 | 5-7 | 220 | 390 | 60 | 20 | 50 | 520 | 70 |

| HBEP-600B | 600 | 4 | DC24 | 5-7 | 220 | 390 | 60 | 20 | 50 | 520 | 78 |

| HBEP-1000B | 1000 | 4 | DC48 | 7-9 | 220 | 490 | 60 | 30 | 60 | 405 | 90 |

Spare Parts

Service

1.Providing standardized and specification-compliant products.

2.Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

1.All products come with an 18-month warranty period.

2.Replacement of damaged components (non-human-induced) is provided during the warranty period.

We offer free technical advice for life to all our customers.

90% of the crane spare parts manufactured in our factory, we are able to supply our customers with the parts they need in the first instance and guarantee their suitability for use.

We provide professional installation teams for customers in need to ensure the safe and effective operation of our products.

We provide over 200 types of cranes and their related products, saving customers’ purchasing time.