Description

The KP series rail cars mainly have :KPX battery power supply, KPJ cable drum power supply, and KPD low-voltage rail power supply methods.Running distance: 0-100M

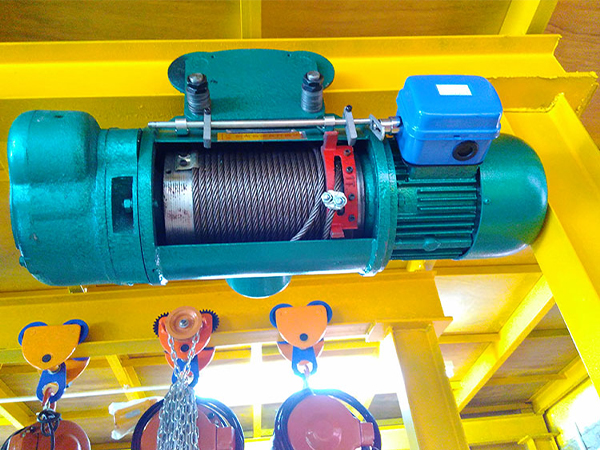

KP cable powered track flat car is a flat car that relies on the winding device of the AC 380V cable to provide power to the flat car. The winding device is placed below the track flat car, and the power is directly controlled by the AC control system to start, stop, move forward, move backward, etc. of the motor. Due to the limitations of cable lines, it is suitable for short distance rail transportation systems, and the operating distance is generally less than 100 meters.

Working Condition

1. Prohibited on rainy days. Because the vehicle is powered by electricity, during transportation, if it rains, there will be a large amount of water accumulation between the tracks, which can easily cause short circuits between the tracks. Therefore, it is not suitable for use on rainy days. If emergency use is indeed necessary, certain protective and drainage measures should be taken to ensure that the power system is not damaged.

2. Cannot be used in environments with high dust density. In production environments with high dust density, the conductivity of the track will decrease, which will affect the operation of electric flatcars

Features

This series of electric flat cars is suitable for harsh environments, high temperature environments, explosion-proof environments, and other occasions;

Due to its simple structure and low cost, it is a common track flat car for workshop crossing;

Compared to the KPX series flat cars, it is not limited by usage time;

Compared to the KPD series flat cars, the requirements for track laying are not high;

Suitable for any load capacity and high frequency of use, with a maximum operating distance of less than 200 meters.

Technical Data

| Model | KPJ-6-2 | KPJ-6-1 | KPJ-16-1 | KPJ-25-1 | KPJ-40-1 | KPJ-63-1 | KPJ-100-1 | KPJ-150-1 | KPJ-200-1 | KPJ-300-1 | ||||||

| KPJ-10-2 | KPJ-10-1 | |||||||||||||||

| Load capacity (t) | 1T | 2T | 16 | 25 | 40 | 63 | 100 | 150 | 200 | 300 | ||||||

| Length (mm) | 3000 | 3600 | 4000 | 4500 | 5500 | 6000 | 8000 | 9000 | ||||||||

| Width (mm) | 1600 | 2000 | 2200 | 2500 | 2800 | |||||||||||

| Height (mm) | ≤440 | ≤480 | ≤580 | ≤620 | ≤850 | ≤1200 | ≤1250 | ≤1350 | ||||||||

| Wheel (piece) | 4 | 8 | 8 | |||||||||||||

| Wheel diameter (mm) | φ360 | φ400 | φ500 | φ600 | φ700 | |||||||||||

| Track gauge (inner side) (mm) | 762 | 1435 | ||||||||||||||

| Wheelbase (mm) | 1700 | 1800 | 2000 | 2500 | 2800 | 3500 | 4500 | 5000 | ||||||||

| Running speed (m/min) | ~30 | ~25 | ~20 | |||||||||||||

| Motor model/powerGround clearance (mm) | YZ132m1-6 / 2.2KW | YZ132m2-6 / 3.7KW | YZ160m1-6/5.5KW | YZ160m2 / 7.5KW | YZ160m2 | 11×2 | 15×2 / 30KW | |||||||||

| 7.5KW×2 | 22KW | |||||||||||||||

| Self weight (T) | ~50 | ~60 | ~70 | |||||||||||||

| Recommended steel rails | ~2.4 | ~2.8 | ~3.5 | ~4.5 | ~5.5 | ~8.2 | ~12 | ~25 | ~29 | ~35 | ||||||

| Remarks | P24 | P38 | P50 | QU100 | QU120 | |||||||||||

| Load capacity (t) | Other table sizes, gauge, and load capacity can be designed and manufactured separately according to user needs. | |||||||||||||||

Spare Parts

Service

1.Providing standardized and specification-compliant products.

2.Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

1.All products come with an 18-month warranty period.

2.Replacement of damaged components (non-human-induced) is provided during the warranty period.

We offer free technical advice for life to all our customers.

90% of the crane spare parts manufactured in our factory, we are able to supply our customers with the parts they need in the first instance and guarantee their suitability for use.

We provide professional installation teams for customers in need to ensure the safe and effective operation of our products.

We provide over 200 types of cranes and their related products, saving customers’ purchasing time.