Description

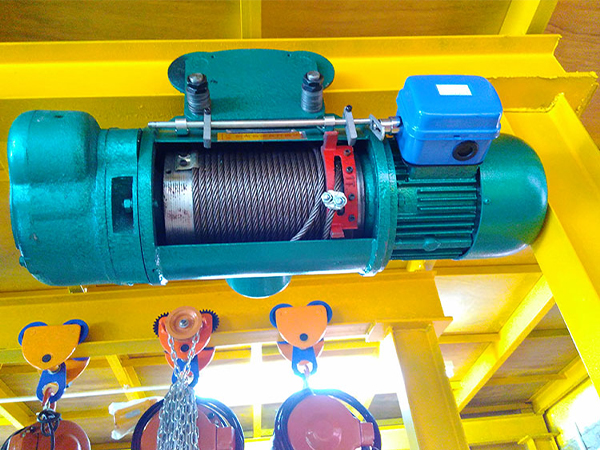

The metallurgical electric hoist is a metallurgical wire rope electric hoist specially designed to transport molten metal or other high-temperature solid items. It can not only be used as an electric single girder, electric suspension, hoist double girder crane and other lifting mechanisms that meet the requirements of use, but also can be independently installed on fixed overhead tracks, which is a safe and reliable light special lifting equipment for small and medium-sized metallurgical workshops. Metallurgical electric hoist Scope of application is suitable for metallurgical industry and is used to transport molten metal.

Working Condition

Working temperature: -10 ℃~+60 ℃

The working level of the lifting mechanism of the metallurgical hoist should not be lower than M6, and the lifting height, lifting speed and operating speed should be in accordance with JB/T 9008.1

Features

The metallurgical electric hoist works at the highest level of M6;

The lift mechanism is composed of support brakes and safety brakes.

Technical Data

| YJCD, YJMD Series Electric Wire Rope Hoist(0.25T-20T) | ||||||||||||||||||||||||||

| Type | YJCD1 YJMD1 | |||||||||||||||||||||||||

| Capacity | T | 0.25 | 0.5 | 1 | 2 | 3 | ||||||||||||||||||||

| Lifting Height | m | 3 | 6 | 9 | 6 | 9 | 12 | 6 | 9 | 12 | 18 | 24 | 30 | 6 | 9 | 12 | 18 | 24 | 30 | 6 | 9 | 12 | 18 | 24 | 30 | |

| Lifting Speed | m/min | 8 | 8/0.8 | 8/0.8 | 8/0.8 | 8/0.8 | ||||||||||||||||||||

| Traveling Speed | m/min | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) | ||||||||||||||||||||

| Wire rope | Rope d | mm | 3.6 | 4.8 | 7.4 | 11 | 13 | |||||||||||||||||||

| Wire d | Mm | 0.22 | 0.34 | 0.5 | 0.6 | |||||||||||||||||||||

| Structural | 6×9 | D-6×37+1 | D-6×37+1 | D-6×37+1 | D-6×37+1 | |||||||||||||||||||||

| track model(GB76-88) | 16-22b | 16-28b | 16-28b | 20a-32c | 20a-32c | |||||||||||||||||||||

Spare Parts

Service

1.Providing standardized and specification-compliant products.

2.Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

1.All products come with an 18-month warranty period.

2.Replacement of damaged components (non-human-induced) is provided during the warranty period.

We offer free technical advice for life to all our customers.

90% of the crane spare parts manufactured in our factory, we are able to supply our customers with the parts they need in the first instance and guarantee their suitability for use.

We provide professional installation teams for customers in need to ensure the safe and effective operation of our products.

We provide over 200 types of cranes and their related products, saving customers’ purchasing time.