Description

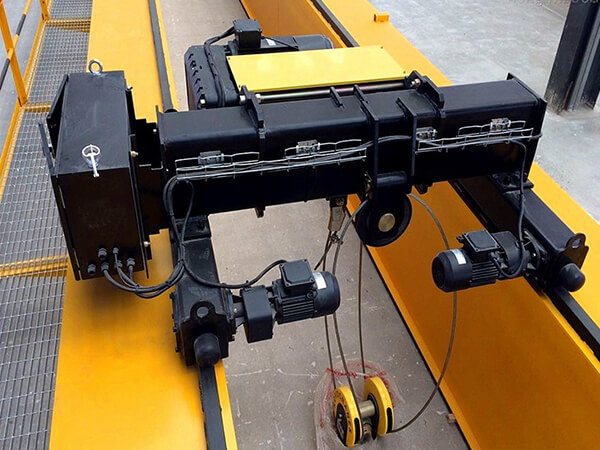

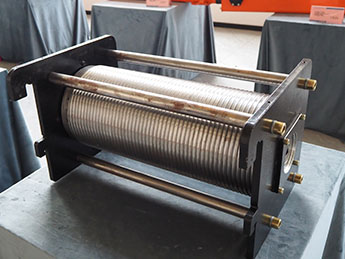

The European double-beam wire rope hoist breaks the design thinking of traditional CD hoists for many years. It takes modular design as the theme. The lifting mechanism adopts planetary gears to transmit speed, making the structure compact and light. It is installed in the drum to effectively reduce the size of the electric hoist. The outer shell adopts a square box structure to change the appearance of the hoist, so that the product can be used in a variety of installation forms. The overall performance of the product is improved, and the cost-effectiveness is fully considered to bring customers more affordable and good products.

Working Condition

This product is suitable for working in an environment with a temperature of -20℃-+40℃.

Features

Accurate positioning, efficient operation, and improved logistics efficiency

The high-quality drive unit ensures safe, stable and efficient operation. The compact structural design ensures that the offset size of the hook is smaller. It provides standard configurations of lifting double speed (variable frequency optional) and trolley variable frequency, ensuring the efficient operation of the crane, the improvement of workshop logistics efficiency, and ensuring that the customer’s various work plans are carried out as scheduled.

The specialized technical product has a variety of monitoring and protection functions to ensure the safe and reliable operation of the crane. Its operation monitoring unit can record the operation of the electric hoist, the motor operation status and the safe working cycle in detail, and warn in advance. All records can provide data for maintenance, understand the root cause of the problem, and make the maintenance of the crane more timely and quick.

Modular design, low maintenance cost, and complete spare parts service

The concept of modular design has been throughout the design of the entire product, ensuring the standardization and interchangeability of components and greatly reducing the maintenance cost of the product. All product lines of the company have a complete inventory of spare parts, and the professional service team ensures that after-sales service is provided to customers in a timely manner to solve the worries of customers after purchasing equipment.

Technical Data

| Capacity (t) | Working class | Liting height (m) | Liting speed (m/min) | Rope reeving | Travelling speed (m/min) | Track distance K(mm) | trolley base distance w(mm) | trolley height B(mm) | hook limit postion H(mm) |

| 5 | M5 | 6 | 5/0.8 | 4/1 | 2-20 | 1600 | 1000 | 449 | 350 |

| 9 | |||||||||

| 12 | |||||||||

| 10 | M5 | 9 | 5/0.8 | 4/1 | 2-20 | 1600 | 1000 | 586 | 500 |

| 12 | 1600 | ||||||||

| 15 | 1600 | ||||||||

| 18 | 2000 | ||||||||

| 24 | 2000 | ||||||||

| 16 | M5 | 9 | 4/0.67 | 4/1 | 2~20 | 2000 | 1200 | 747 | 850 |

| 12 | 2000 | ||||||||

| 15 | 2400 | ||||||||

| 18 | 2600 | ||||||||

| 20 | M5 | 9 | 4/0.67 | 4/1 | 2~20 | 2000 | 1200 | 747 | 850 |

| 12 | 2000 | ||||||||

| 15 | 2400 | ||||||||

| 18 | 2600 | ||||||||

| 24 | 3000 | ||||||||

| 32 | M5 | 8 | 2.7/0.45 | 6/1 | 2~20 | 2400 | 1200 | 784 | 900 |

| 10 | 2400 | ||||||||

| 12 | 2400 | ||||||||

| 16 | 2400 | ||||||||

| 32 | M5 | 6 | 0.82~4.9 | 8/2 | 2~20 | 2400 | 1200 | 740 | 1520 |

| 9 | 2400 | ||||||||

| 13.5 | 2800 | ||||||||

| 18 | 3300 | ||||||||

| 50 | M5 | 6 | 0.53~3.2 | 12/2 | 2~20 | 2400 | 1600 | 800 | 1400 |

| 9 | 2800 | ||||||||

| 12 | 3300 | ||||||||

| 15 | 3800 | ||||||||

| 18 | 4200 | ||||||||

| 80 | M5 | 6.5 | 0.5~2.4 fequency conversion | 16/2 | 2~20 | 2900 | 2500 | 951 | 1860 |

| 9 | 3400 | ||||||||

| 11 | 3800 | ||||||||

| 15 | 4500 |

Spare Parts

Service

1.Providing standardized and specification-compliant products.

2.Providing customized product solutions based on different working conditions, temperature, type, voltage, etc.

1.All products come with an 18-month warranty period.

2.Replacement of damaged components (non-human-induced) is provided during the warranty period.

We offer free technical advice for life to all our customers.

90% of the crane spare parts manufactured in our factory, we are able to supply our customers with the parts they need in the first instance and guarantee their suitability for use.

We provide professional installation teams for customers in need to ensure the safe and effective operation of our products.

We provide over 200 types of cranes and their related products, saving customers’ purchasing time.