The introduction of this crane aims to enhance operational efficiency in the logistics and manufacturing sectors, meeting the growing market demands in Indonesia.

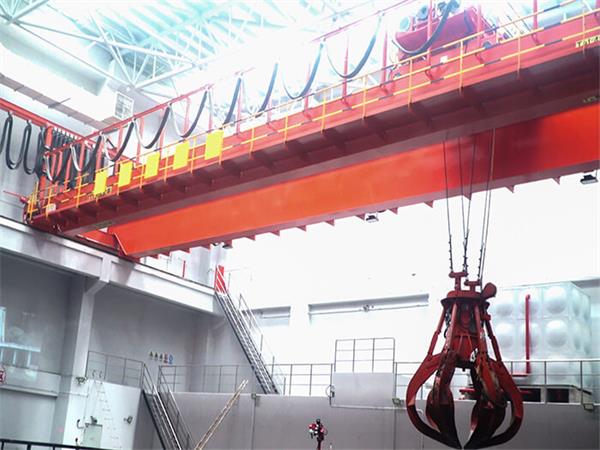

Double Beam Structure Design: The adoption of a double beam structure enhances overall stability and load-bearing capacity, making it suitable for efficient handling of heavy materials.

Wide Tonnage Range: It can meet various lifting requirements in different process stages of the hot-rolling steel plant, with flexible utilization ranging from 10 to 100 tons.

Electromagnetic Adsorption System: Incorporating advanced electromagnetic adsorption technology enables rapid and secure adsorption and release of ferromagnetic materials, facilitating more flexible and precise control.

Intelligent Control System: Equipped with an advanced automation control system, it achieves precise control over the crane, maximizing operational efficiency.

Customized Adaptation: Tailored to project requirements, the crane allows flexible customization of span and other technical parameters to better suit specific industrial scenarios.

This project aims to propel Indonesia’s logistics and manufacturing industries towards a more intelligent and efficient direction. The introduction of these technical highlights enables the crane to adapt to diverse operational needs, providing advanced technological support for improving production efficiency and reducing operational costs.

MH type electric hoist gantry crane is used together with CD MD model electric hoists.

L Type electric hoist gantry crane match with CD1/ MD1, HC type Electric Wire rope hoist, to lifting and transporting the heavy materials, mainly use indoors and outdoors.

BMH Type Semi Gantry Crane is a bridge-type crane whose bridge is supported on the ground track through outriggers on both sides.

A-type Double Beam Hook Gantry Crane, It is mainly composed of a gantry (main beam, outriggers, lower beam, etc.), a lifting mechanism, a running mechanism and an electronic control part.

The rail-mounted container gantry crane (English abbreviation RMG) is one of the special machines for container yards.

MZ Type Double-beam Grab Gantry Crane are mainly used in conjunction with bridge cranes, port cranes, and winches. They are widely used in ports, power plants, docks, chemical industries, etc. to grab various types of loose accumulations, such as ore, coal, slag, etc.

Winch Gantry Crane are used in open warehouses, windy areas, material stocks area, bridge building, concrete industry, cement plant, granite industry, construction industry, engineering industry, port, transportation, construction, dockyard, and other building sites for lifting and loading unloading objects.

U Type Subway Turn Slag Hook Gantry Crane also known as subway slag flipping machine, slag flipping gantry crane, slag flipping gantry crane, etc., is a specialized gantry crane used for excavation in subway and tunnel construction projects.

Russia Krasnodar port is located in the south of Russia, because it is located in Siberia, high latitude, cold climate, long winter, in the design of the crane steel structure, mechanism parts and…

Our company conducted in-…

Russia Krasnodar port is located in the south of Russia, because it is located in Siberia, high latitude, cold climate, long winter, in the design of the crane steel structure, mechanism parts and…

Russia Krasnodar port is located in the south of Russia, because it is located in Siberia, high latitude, cold climate, long winter, in the design of the crane steel structure, mechanism parts and…

Russia Krasnodar port is located in the south of Russia, because it is located in Siberia, high latitude, cold climate, long winter, in the design of the crane steel structure, mechanism parts and…

Russia Krasnodar port is located in the south of Russia, because it is located in Siberia, high latitude, cold climate, long winter, in the design of the crane steel structure, mechanism parts and…

We design cranes that meet your needs. Whether you need to increase safety, maximize production capacity or reliability, or reduce costs, we deliver.